|

GMC

Sound Pressure Level Competition Van

Sound level competition became a hobby and a personal drive

during employment at Carls Stereo on Wheels.

The van was purchase one year prior, as a rehabilitation project

and daily driver. A new

engine and interior, including seats and carpet, was installed for

reliability and personal enjoyment.

The competition conversion was initiated following a conversation

with Carl, company owner, regarding possible arrangement for an intense

product representation and competition vehicle for the companys

customers and employees. The

Installation labor and supply cost was arranged to be my responsibility.

Stereo equipment, including speakers, wire, connectors,

alternators, amplifiers, batteries, radio, and extras was provided by

Carl.

S.P.L. conversion for the van lasted more than one year; this was

a period of time requiring intense personal sacrifices and creative

personal best. The initial

steps of the process involved an intense educational process that lasted

the complete dedicated era. Different

enclosures provided a plethora of enlightening experiences.

Each new experience provided new possible creative ideas which

sometimes lead to a new enclosure design

The initial design utilized sixteen fifteen-inch MTX subwoofers,

eight MTX seven-hundred watt amplifiers, and eight yellow top Optima

batteries. The enclosure

provided an intense free air, doors open, high pressure sound vehicle. The

resonant frequency was recorded to be approximately 80Hz.

The van was entered into its first sound pressure level (S.P.L)

competition and was rewarded a first place trophy and money order of

two-hundred fifty dollars. The

van provided a pressure recording of 158 db, during the contest, off the

windshield, with the doors closed. This

experience provided an accouchement to an intense drive for the highest

sound pressure possible.

Analysis

of the first enclosure, through trial and error, provided results

regarding pressure cancellation. The

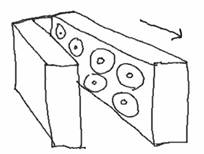

sideways V configuration in picture 1, with eight subs on each arm

of the V with four apposing the accompanying four allowed for an

efficient way to install all sixteen into the van, perpendicular to the

automobile floor. Enclosure

construction utilized medium density fiberboard (M.D.F), fiberglass

resin, and fiberglass mat. My analysis provided information that

cancellation occurs with the front eight subwoofers.

The rear eight connected individually, without the front eight

and with only 4 amplifiers, provided the same S.P.L results recorded at

the competition. I

understood that the speaker enclosure would be useless if the enclosed

space allowed for more than two speakers deep. Stopping

examination at this point would only provide a theory without proof.

|

Picture

1

|

|

|

A new enclosure was the only way to provide proof for my analysis.

The second enclosure design accreted from analysis of other

competition vehicles and my personal experiences.

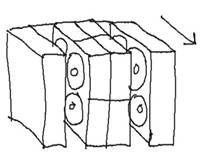

The new design was similar to a UU shape on its side with

four speakers on each arm of the U, perpendicular to the auto

floor. Picture 2 provides

some insight to the duel U design.

This enclosure provided enough space for sixteen subwoofers to be

installed behind the door jambs and eight amplifiers.

Each center single subwoofer had an individual enclosure, 1.5

cubic foot, for easy speaker removal.

Depth between the front of the center enclosures and the edge

enclosures was only ten inches. The

distance further provided additional problems with pressure

cancellation. Removal of the

center enclosures, provided a single wider U shape on its side,

proved to allow for a slightly higher S.P.L than the original V

enclosure due to the shorter travel distance for the reflection off of

the rear of the enclosure. The

adequate resonant frequency resulted in 80Hz, the same as the V

enclosure. Further

investigation resulted in additional information that the flat portion

of the rear of the enclosure and a wide distance between apposing

speakers provide increase reduction in sound cancellation.

The new enclosure did not provide the desired increase in sound

pressure and did not allow for the preferred amount of electronic

equipment. An additional,

third, enclosure must be designed for more equipment and pressure

increase.

|

Picture

2

|

|

|

The third enclosure design provided mounting locations for only

twelve fifteen-inch subwoofers and six amplifiers.

A U enclosure design was configured to allow the subwoofers

to be mounted above and below each other with six on the top U arm

and six on the bottom U arm, horizontally mounted to the auto

floor. The rear of the

enclosure was designed to have a flat reflective surface.

Opposing speakers had ample distance from each other and apposing

was no further than two deep. Completion

of this enclosure provided an increase in pressure recording.

Further enhancement investigation loosened hidden important

information about side to side apposing separation applied to more than

distance from the microphone. Dividing

the enclosure in to three separate U enclosures side by side

provided a decrease in sound cancellation.

The enclosure provided a recorded S.P.L. competition score of 164

db. This pressure level

allowed the vehicle to place a third position at the local S.P.L. final

competition. This enclosure

provided its highest pressure recording at 82Hz with the rear of the

enclosure located at approximately 72 inches from the microphone.

During the competition, I noticed that the first and second place

competitors provided a higher frequency to their vehicle during the

competition. I confronted

them with questions regarding their frequency analysis experience.

One of the competitors informed me that the resonant frequency

change was able to be changed with enclosure volume size.

An additional competitor allowed the information that his

competition auto can respond to individual and both 80Hz and 120Hz

frequency range. I took this

important information and analyzed every connection and configuration of

their vehicles. The

automobiles had similar enclosures with obvious pressure cancellation

issues that were experienced with my enclosures.

|

Picture

3

|

Picture

4

|

Picture

5

|

A personal drive initiated an additional enclosure with six

V shaped enclosures. Each

V shaped enclosure had only one subwoofer inverted on each arm,

horizontally mounted speaker cone to the automobile floor. The enclosure

was installed directly behind the door jambs.

The center six enclosures had useful design aspect to allow for

separate enclosure removal and speaker replacement.

Each enclosure supplied the desired 1.5 cubic-foot enclosure for

individual speakers. This

enclosure was derived from the allowance for possible decrease in

pressure cancellation due to the decrease in speaker apposition.

Pressure results decreased due to the use of 80Hz frequency

spectrum. The decrease in

S.P.L was not understood at the time.

This enclosure adsorbed a large amount of time and was not

providing desired results. My

analysis informed me that the distance from the microphone to the rear

of the enclosure must be in the range of 72 inches.

Destruction of the supposed perfect enclosure happened

prematurely.

|

Picture

6

|

Picture

7

|

Picture

8

|

|

Picture

9

|

Enclosure officially numbered five, not including the redesigns

of the previous enclosures, allowed for the creation of a three half

polygon enclosure that could be installing at a varied distance from the

microphone for testing. The

enclosure allowed sufficient mounting locations for twelve subwoofers

and six amplifiers. Each

subwoofer cone was mounted at a 45Ί parallel to the auto floor.

Each of the straight portions of the polygon arms had two

subwoofers mounted perpendicular to the windshield.

Design of the enclosure came about from analysis of the first

place competitor of the local S.P.L. competition.

Considering that his enclosure build had a low amount of

cancellation issues than all of the other competitor enclosures, he also

had a very high pressure result. His

enclosure had fifteen subwoofers, with five in each half polygon shape.

Number five enclosure only provided four subwoofers in each half

polygon to reduce pressure cancellation. Experimentation

with this versatile enclosure provided answers to a variety of

questions. Enclosure

distance from the windshield, microphone, for 80Hz and 120Hz was solved.

At 80Hz, each of the twelve separate enclosure size seemed to be

prevalent at 1.5 cubic-feet with the reflective rear of the enclosure

located at 72 inches. The

120Hz response prevailed when each of the individual twelve subwoofer

enclosure was provided with a very small amount of air.

Each of the 120Hz enclosures responded with higher S.P.L. when

the enclosure was decreased as it was further from the microphone.

The optimal distance of the enclosure reflective rear, for higher

frequencies, was directly behind, allowed distance, the door jamb.

This enclosure provided new information about resonant frequency

response due to enclosure size, distance from microphone, fiberglass

resin and mat use, and a final lesson which allowed for an increase of

over 5db. The increase for

over 5db was provided due to sealing the air circulation system of the

vehicle and lining the interior of the vehicle with M.D.F. and

fiberglass resin. AIR

TIGHT!!!!! Following the air

tight revolution the van created a ground-breaking pressure recording of

172db. I broke the 170db

mark with 120Hz resonance frequency!!!

|

Picture

9

|

Picture

10

|

Picture

11

|

After the completion of the vehicle, new information was

introduced to me about the competition rules.

The 120Hz range was not acceptable due to the lack of rumble for

the spectators. After the

disappointment subsided, I change the enclosure and concerted it to a

rumbling and loud sales vehicle that played a variety of music.

The conversion process included an experience with body work and

paint which is information for a different story.

The final pictures of the van without equipment are located

below.

|

Picture

12

|

Picture

13

|

Picture

14

|

|

Picture

15

|

Picture

16

|

Picture

17

|

|

Picture

18

|

Picture

19

|

Picture

20

|

Completion of the 120Hz enclosure provided important information

which could have allowed the six V enclosures to surpass all of

the other designs. I did not

receive addition opportunities to critique the design for optimization.

The next sealed S.P.L competition enclosure for fifteen-inch

subwoofers will be a similar reproduction of the six-V at the correct

distance for the frequency and enclosure air space size.

|

|