- Remove the fuel cap.

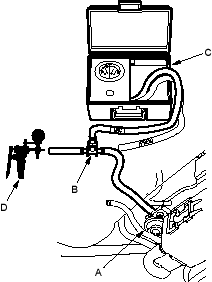

- Disconnect the vapour line from the EVAP two way valve (A). Connect it to a T-fitting (B) from the vacuum gauge (C) and the vacuum pump (D) as shown.

- Apply vacuum slowly and continuously while watching the gauge.

The vacuum should stabilise momentarily at 0.8-2.1 kPa (6-16 mmHg, 0.2-0.6 in.Hg).

If the vacuum stabilises (valve opens) below 0.8 kPa (6 in.Hg), or above 2.1 kPa (16 mmHg, 0.6 in.Hg), install a new valve and retest.

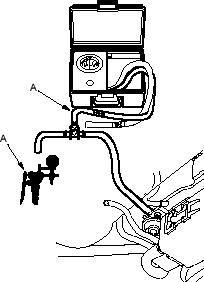

- Move the vacuum pump hose from the vacuum fitting to the pressure fitting, and move the vacuum gauge hose from the vacuum side to the pressure side (A) as shown.

- Slowly pressurise the vapour line while watching the gauge. The pressure should stabilise momentarily above 1.0 kPa (8 mmHg, 0.3 in.Hg).

- If the pressure momentarily stabilises (valve opens) above 1.0 kPa (8 mmHg, 0.3 in.Hg), the valve is OK.

- If the pressure stabilises below 1.0 kPa (8 mmHg, 0.3 in.Hg), install a new valve and retest.