DTC P0325: Knock Sensor Circuit Malfunction

- Reset the ECM/PCM (see page 11-312).

- Start the engine. Hold the engine at 3,000 rpm (min-1) with no load (in Park or neutral) until the radiator fan comes on, then let it idle.

- Hold the engine at 3,000-4,000 rpm (min-1) for at least 60 seconds.

Is DTC P0325 indicated?

YES |

- Go to step 4. |

NO |

- Intermittent failure, system is OK at this time. Check for poor connections or loose wires at the knock sensor and at the ECM/PCM. |

- Turn the ignition switch OFF.

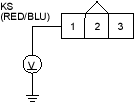

- Disconnect the knock sensor 3P connector.

- Turn the ignition switch ON (II).

- Measure voltage between knock sensor 3P connector terminal No. 1 and body ground.

Is there about 5 V?

YES |

- Go to step 12. |

NO |

- Go to step 8. |

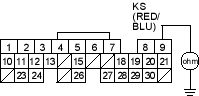

- Measure voltage between ECM/PCM connector terminal A9 and body ground.

Is there about 5 V?

YES |

- Repair open in the wire between the ECM/PCM (A9) and knock sensor. |

NO |

- Go to step 9. |

- Turn the ignition switch OFF.

- Disconnect ECM/PCM connector A (31P).

- Check for continuity between ECM/PCM connector terminal A9 and body ground.

Is there about 5 V?

YES |

- Repair short in the wire between ECM/PCM (A9) and knock sensor. |

NO |

- Substitute a known-good ECM/PCM and recheck (see page 11-313). If symptom/indication goes away, replace the original ECM/PCM. |