|

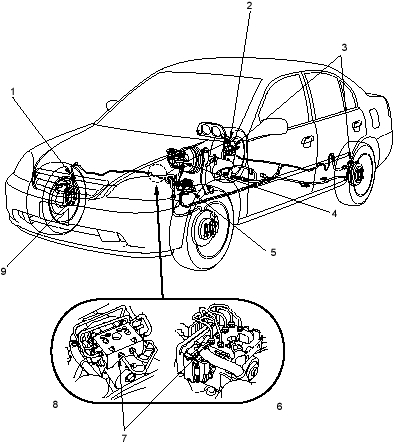

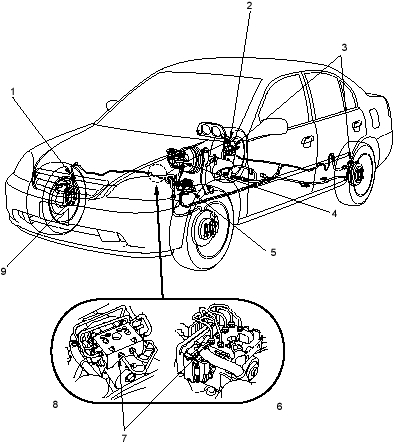

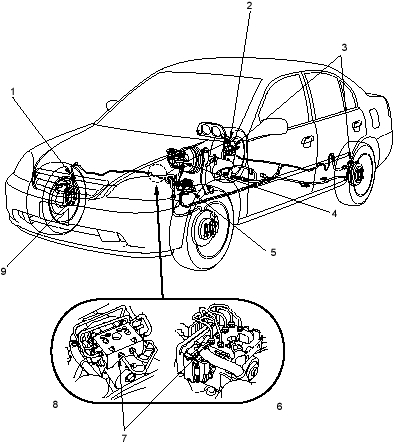

- BRAKE LINE-to-BRAKE HOSE

15 Nm (1.5 kgf/m, 11 lbf/ft)

- BRAKE LINE-to-BRAKE HOSE

15 Nm (1.5 kgf/m, 11 lbf/ft)

- BRAKE LINE-to-WHEEL CYLINDER

15 Nm (1.5 kgf/m, 11 lbf/ft)

BLEED SCREW

7 Nm (0.7 kgf/m, 5 lbf/ft)

- MASTER CYLINDER-to-BRAKE LINE

15 Nm (1.5 kgf/m, 11 lbf/ft)

- PROPORTIONING CONTROL VALVE-to-BRAKE LINE

15 Nm (1.5 kgf/m, 11 lbf/ft)

- On Vehicles Manufactured in Suzuka Plant

- ABS MODULATOR UNIT-to-BRAKE LINE

15 Nm (1.5 kgf/m, 11 lbf/ft)

- On Vehicles Manufactured in Other Plants

- BRAKE HOSE-to-CALLIPER, (BANJO BOLT)

34 Nm (3.5 kgf/m, 25 lbf/ft)

BLEED SCREW

9 Nm (0.9 kgf/m, 7 lbf/ft)

|