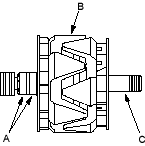

Rotor Slip Ring Test

- Check that there is continuity between the slip rings (A).

- If there is continuity, go to step 17.

- If there is no continuity, replace the rotor assembly.

- Check that there is no continuity between each slip ring (A) and the rotor (B) and the rotor shaft (C).

- If there is no continuity, replace the rear housing assembly, go to step 18.

- If there is continuity, replace the rotor assembly.

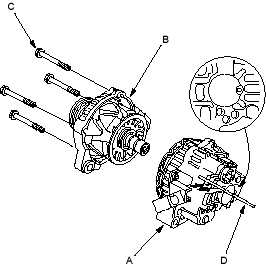

Alternator Reassembly

- If you removed the pulley, put the rotor in the drive-end housing, then tighten its locknut to 111 Nm (11.3 kgf/m, 81.7 lbf/t).

- Remove any grease or any oil from the slip rings.

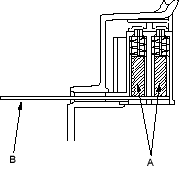

- Push the brushes (A) in, then insert a pin or drill bit (B) (about 1.8 mm (0.77 in.) diameter) to hold them there.

- Heat the rear bearing seat with a 1,000 W hair drier for about 5 minutes (50 - 60oC, 129 - 140oF).

- Put the rear housing assembly (A) and drive-end housing/rotor assembly (B) together, tighten the four through bolts (C) and pull put the pin (D).

- After assembling the alternator, turn the pulley by hand to make sure the rotor rotates smoothly and without noise.

- Reinstall the alternator, and adjust its belt tension (see page 4-37).