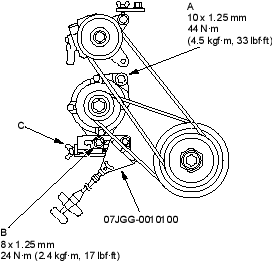

Special Tools Required

Belt Tension Gauge, 07JGG-0010100

Belt Tension Gauge Method

Inspection

- Attach the belt tension gauge to the belt and measure the tension. Follow the gauge manufacturer's instructions. If the belt is worn or damaged, replace it. If the belt needs adjustment, go to step 2.

Tension:

Used Belt: 340 - 490 N (35 - 50 kgf, 77 - 110 lbf) New Belt: 540 - 740 N (55 - 75 kgf, 120 - 170 lbf)

Adjustment

- Loosen the mounting bolt (A),lock bolt (B) and lower bracket mounting bolt mounting bolt (C).

- Torque the mounting bolt to 20 N.m (2.0kgf.m,14 lbf.ft).

- Turn the adjusting bolt (D) to obtain the proper belt tension, then retighten the lock bolt, mounting bolt and lower bracket mounting bolt.

- Recheck the belt tension.

- If you installed a new belt, run the engine for 5 minutes, then readjust the belt to the used belt specification.

- Check the power steering pump belt adjustment (see page 17-12).

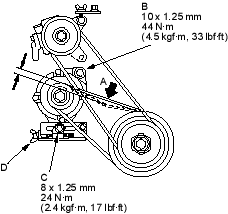

Deflection Method

Inspection

- Apply a force of 98 Nm (10 kgf, 22 lbf), and measure the deflection at the mid point (A) between the alternator and crankshaft pulley. If the belt is worn or damaged, replace it. If the belt needs adjustment, go to step 2.

Deflection:

Used Belt: 8.5 - 11.0 mm (0.33 - 0.43 in.) New Belt: 6.5 - 8.5 mm (0.26 - 0.33 in.)

Adjustment

- Loosen the mounting bolt (B),lock bolt (C) and lower bracket mounting bolt mounting bolt (D).

- Torque the mounting bolt to 20 N.m (2.0kgf.m,14 lbf.ft).

- Turn the adjusting bolt (E) to obtain the proper belt tension, then retighten the lock bolt, mounting bolt and lower bracket mounting bolt.

- Recheck the belt tension.

- If you installed a new belt, run the engine for 5 minutes, then readjust the belt to the used belt specification.

- Check the power steering pump belt adjustment (see page 17-12).