- Warm up the engine to normal operating temperature (cooling fan comes on).

- Turn the ignition switch OFF.

- Remove the air cleaner housing (see step 6 on page 6-29).

- Disconnect all four injector connectors.

- Start the engine and let it run until it stalls.

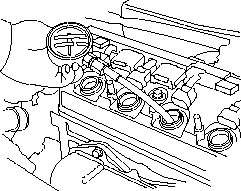

- Remove the all four ignition coils (see page 4-24).

- Remove the all four spark plugs.

- Attach the compression gauge to the spark plug hole.

- Connect a tachometer.

- Open the throttle fully, then crank the engine with the starter motor and measure the compression.

Compression Pressure:

Above 930 kpa (9.5 kgf/cm2, 135 psi)-250 rpm (min-1)

- Measure the compression on the remaining cylinders.

Maximum variation:

Within 200 kPa (2.0 kgf/cm2, 28 psi)

- If the compression is not within specifications, check the following items, then remeasure the compression.

- Damaged or worn valves and seats

- Damaged cylinder head gasket

- Damaged or worn piston rings

- Damaged or worn piston and cylinder bore