Straightness

NOTE:

- Clean the crankshaft oil passages with pipe cleaners or a suitable brush.

- Check the keyway and threads.

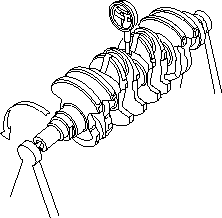

- Support the crankshaft with a lathe-type tool or V-blocks.

- Measure runout on all main journals to make sure the crank is not bent. Rotate the crankshaft two complete revolutions. The difference between measurements on each journal must not be more than the service limit.

Crankshaft Total Indicator Runout:

| Standard (New): | 0.03 mm (0.001 in.) max. |

| Service Limit: | 0.04 mm (0.002 in.) |

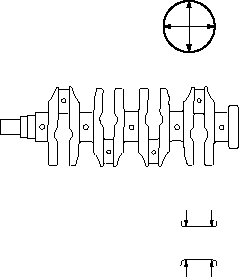

- Measure out-of-round at the middle of each rod and main journal in two places. The difference between measurements on each journal must not be more than the service limit.

Journal Out-of-Round:

| Standard (New): | 0.0025 mm (0.0001 in.) max. |

| Service Limit: | 0.005 mm (0.0002 in.) |

- Measure taper at the edge of each rod and main journal. The difference between measurements on each journal must not be more than the service limit.

Journal Taper:

| Standard (New): | 0.0025 mm (0.0001 in.) max. |

| Service Limit: | 0.005 mm (0.0002 in.) |