|

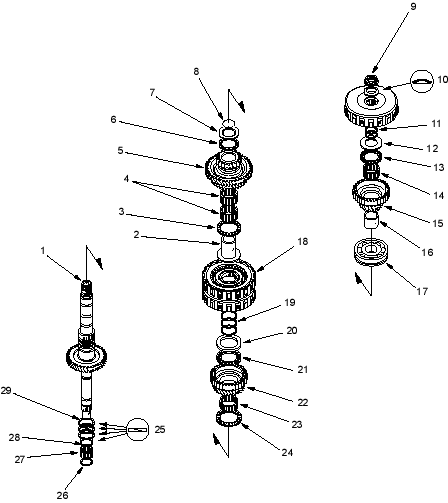

- MAINSHAFT

- 4TH GEAR COLLAR

- THRUST NEEDLE BEARING

- NEEDLE BEARING

- 4TH GEAR

- THRUST NEEDLE BEARING

- THRUST WASHER

- SNAP RING

- LOCKNUT (FLANGE NUT)

21 x 1.25 mm, 79 Nm (8.0 kgf/m, 58 lbf/ft)

Replace.

Left-hand threads.

- CONICAL SPRING WASHER, Replace.

- O-RINGS, Replace.

- THRUST WASHER

- THRUST NEEDLE BEARING

- NEEDLE BEARING

- 1ST GEAR

- 1ST GEAR COLLAR

- TRANSMISSION HOUSING BEARING

- 2ND/4TH CLUTCH

- O-RING, Replace

- THRUST WASHER

36.5 x 55 mm

Selective part.

- THRUST NEEDLE BEARING

- 2ND GEAR

- NEEDLE BEARING

- THRUST NEEDLE BEARING

- Install sealing ring mating surface as shown.

- SET RING

- NEEDLE BEARING

- SEALING RING, 29 mm

- SEALING RINGS, 35 mm

|