|

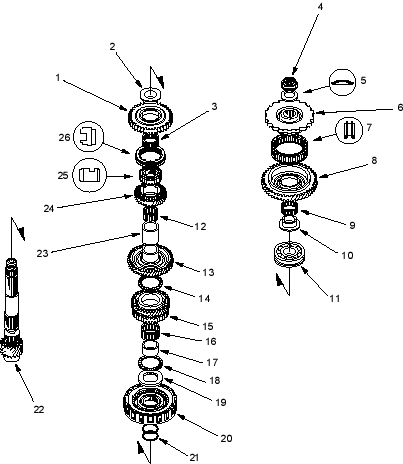

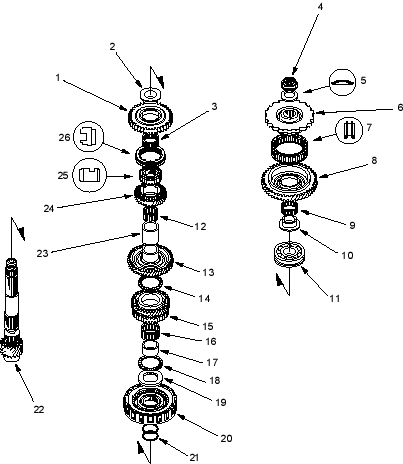

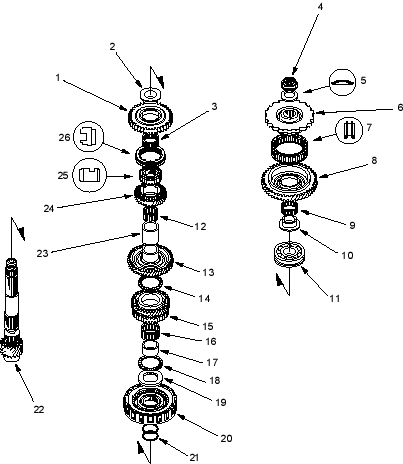

- REVERSE GEAR

- REVERSE GEAR COLLAR

- NEEDLE BEARING

- LOCKNUT (FLANGE NUT)

23 x 1.25 mm, 103 Nm (10.5 kgf/m, 75.9 lbf/ft) – 0-103 Nm (10.5 kgf/m, 75.9 lbf/ft)

- CONICAL SPRING WASHER

Replace

- PARK GEAR

- ONE-WAY CLUTCH

- 1ST GEAR

- NEEDLE BEARING

- 1ST GEAR COLLAR

- TRANSMISSION HOUSING COUNTERSHAFT BEARING

- NEEDLE BEARING

- 2ND GEAR

- THRUST NEEDLE BEARING

- 3RD GEAR

- NEEDLE BEARING

- 3RD GEAR COLLAR

- THRUST NEEDLE BEARING

- SPLINED WASHER

- 3RD CLUTCH

- O-RINGS, Replace

- COUNTERSHAFT

- DISTANCE COLLAR, 28 mm

Selective part

- 4TH GEAR

- REVERSE SELECTOR HUB

- REVERSE SELECTOR

|