- Do not rotate the camshaft during inspection.

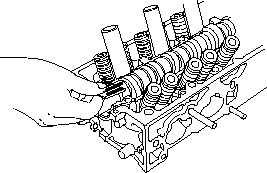

- Remove the rocker arms and rocker shafts.

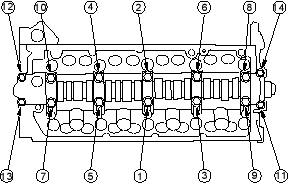

- Put the camshaft and the camshaft holders on the cylinder head, then tighten the bolts to the specified torque.

Specified torque:

8 mm bolts: 20 Nm (2.0 kgf/m, 14 lbf/ft) Apply engine oil to the bolt threads. 6 mm bolts: 12 Nm (1.2 kgf/m, 8.7 lbf/ft) Apply engine oil to the bolt threads. 6 mm bolts: (11), (12), (13), (14)

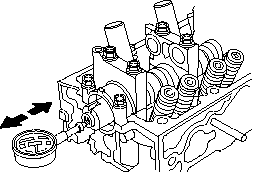

- Seat the camshaft by pushing it away from the camshaft pulley end of the cylinder head.

- Zero the dial indicator against the end of the camshaft, then push the camshaft back and forth and read the end play.

Camshaft End Play:

Standard (New): 0.05 - 0.15 mm (0.002 - 0.006 in.)

Service Limit: 0.5 mm (0.02 in.)

- Unscrew the camshaft holder bolts 2 turns at a time, in a criss-cross pattern. Then remove the camshaft holders from the cylinder head.

- Lift the camshaft out of the cylinder head, wipe them clean, then inspect the lift ramps. Replace the camshaft if any lobes are pitted, scored, or excessively worn.

- Clean the camshaft journal surfaces in the cylinder head, then set the camshaft back in place. Place a plastigage strip across each journal.

- Install the camshaft holders, then tighten the bolts to the specified torque as shown in step 1.

- Remove the camshaft holders. Measure the widest portion of plastigage on each journal.

- If the camshaft-to-holder clearance is within limits, go to step 10.

- If the camshaft-to-holder clearance is beyond the service limit and the camshaft has been replaced, replace the cylinder head.

- If the camshaft-to-holder clearance is beyond the service limit and the camshaft has not been replaced, go to step 9.

Camshaft-to-Holder Oil Clearance:

Standard (New): |

0.050 - 0.089 mm (0.0020 - 0.0035 in.) |

Service Limit: |

0.15 mm (0.006 in.) |