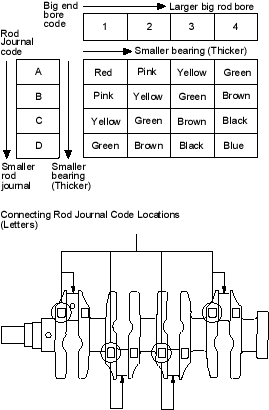

Rod Bearing Selection

Each rod falls into one of four tolerance ranges (from 0 to 0.024 mm (0.0009 in.), in 0.006 mm (0.0002 in.) increments) depending on the size of its big end bore.

It's then stamped with a number (1,2,3, or 4), indicating the range.

You may find any combination of 1, 2, 3, or 4 in any engine.

Normal Bore Size:

D14Z5 engines: 43.0 mm (1.69 in.)

D15Y2, D15Y3, D15Y4, D15Y5, D15Y6 engines: 45.0 mm (1.77 in.)

D16V1, D16W7, D16W8, D17Z1, D17Z2, D17Z3, D17A1, D17A2, D17A5 engines: 48.0 mm (1.89 in.)

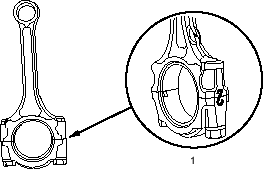

Inspect the connecting rod for cracks and heat damage.

Connecting Rod Journal Code Locations

Numbers have been stamped on the side of each connecting rod as a code for the size of the big end. Use them, and the letters stamped on the crank (codes for rod journal size), to choose the correct bearings. If the codes are indecipherable because of an accumulation of dirt and dust, do not scrub them with a wire brush or scraper. Clean them only with solvent or detergent.

- Half of number is stamped on bearing cap and the other half is stamped on rod.