If the crankshaft is already installed

- Set the crankshaft to BDC for each cylinder.

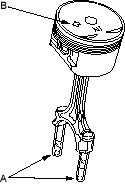

- Remove the connecting rod caps and slip short sections of rubber hose (A) over the connecting rod bolts. Then install the ring compressor, and check that the bearing is securely in place.

- Position the arrow (B) facing the timing belt side of the engine.

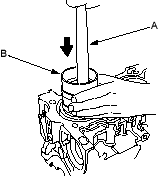

- Position the piston in the cylinder and tap it in using the wooden handle of a hammer (A).

Maintain downward force on the ring compressor (B) to prevent the rings from expanding before entering the cylinder bore.

- Stop after the ring compressor pops free, and check the connecting rod-to-crank journal alignment before pushing the piston into place.

- Check the connecting rod bearing clearance with plastigage (see page 7-9).

- Apply engine oil to the bolt threads, then install the rod caps with bearings. Torque the nuts to 32 Nm (3.3 kgf/m, 24 lbf/ft).

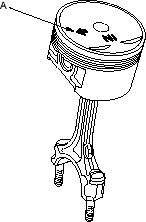

- Remove the connecting rod caps, then install the ring compressor, and check that the bearing is securely in place.

- Position the arrow (A) facing the timing belt side of the engine.

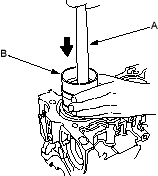

- Position the piston in the cylinder and tap it in using the wooden handle of a hammer (A).

Maintain downward force on the ring compressor (B) to prevent the rings from expanding before entering the cylinder bore.

- Position all pistons at top dead centre.